(Examples of cards include: PCV, redemption, shopping, points, gift, supermarket, etc.)

In recent years, the number of cards being printed for gift and merchandise exchanges has increased dramatically. In this regard, we visited nearly 1,000 card manufacturers around the world and found that nearly 90% of factories are manually discharging cards through manual printing or labeling.

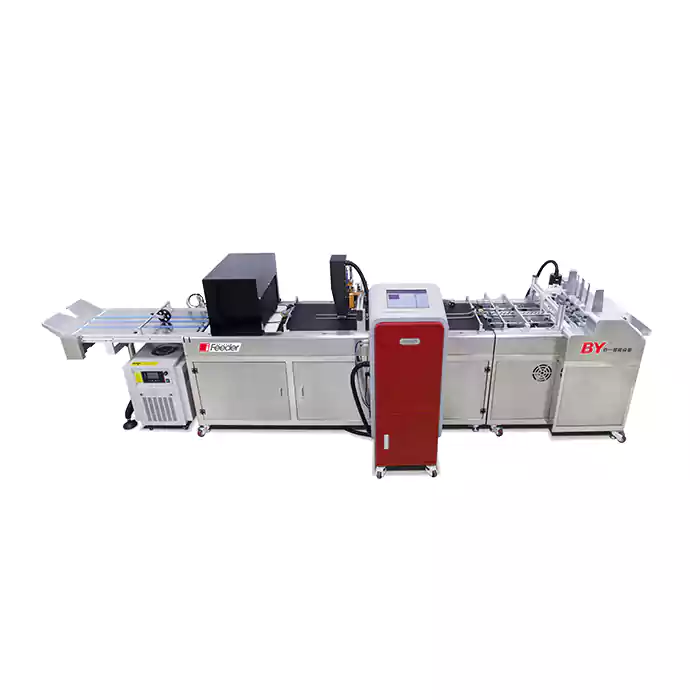

We have successfully developed this system while collecting opinions from factories: High-speed friction feed inkjet printing, photo inspection and labelling integrated system.

And what are its components?

1. High-speed friction feeder: as the main operating platform, with a 260mm high storage bin, workers only need to continuously to the storage bin stacked material, the product through the friction of the way a sheet transferred to the automatic guiding mechanism for position correction, and then transferred to the conveyor belt; In the conveyor belt for a series of inkjet printers, if a product is deemed unqualified or unsuitable for printing, the system will not proceed with labelling. The product will be rejected and removed from the production line.

Once the product has passed the print test, the system will issue a labelling action for the product, which will then enter the storage mechanism for qualified products after labelling.

2. UV inkjet printer: mainly by the plasma processor (treatment surface stronger ink adhesion) + UV inkjet print head and control cabinet + UV curing lamp (drying) components

3.Visual inspection system: mainly composed of camera + monitor + keyboard + mouse + real-time photo inspection system

4. Automatic labelling system: complete labelling mechanism and system

What is the impact of this system on card manufacturing plants?

The automatic feeding machine is capable of operating at a much higher speed than a manual discharge system. This has led to a significant improvement in output and efficiency.

The introduction of a visual inspection system will replace the manual, one-by-one checking of print content for errors, missed prints and no prints.