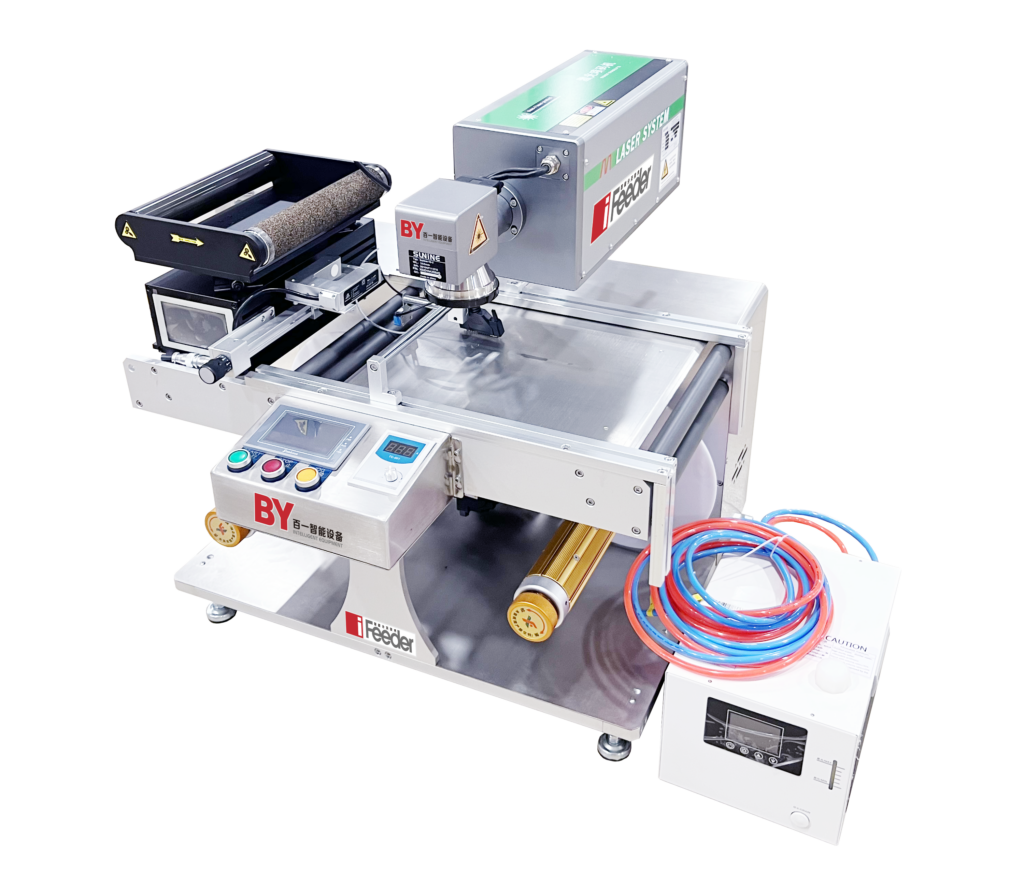

Rewinder Machine

With a self-developed linear unwind and tension control system for efficient and precise printing, labeling, and rewinding processes.

- Rewinding Accuracy - 0.2 to 0.2mm

- Desktop and Floor Mounted

- Multifunctional Integration

Reliable Rewinder Machine Supplier

iFeeder has been a specialized rewinder machine manufacturer for fourteen years. We focus on providing customers with tabletop rewinders, automatic label rewinder machines, stretch film rewinders, ribbon rewinders, paper rewinders, aluminum foil rewinders, etc. We offer rewinder machine solutions and integrated coding, spotting, and labeling applications to your specific needs. Increasing productivity for your rolled products.

Related Recommended Products

Benefits from iFeeder Rewinder Machine

We constantly explore market needs and endeavour to solve problems for our customers.

Downtime Prevents Loosening

To prevent unwinding or deformation of the wound material due to self-weight or other external forces when the rewinder machine stops working.

Real-time Counting Function

Rewinders are able to count the number of completed rolls of material in real time, which is very helpful for production planning, progress tracking, and inventory management.

White or Color-coded Trigger Sensors

We install photoelectric sensors or other sensors, the system can automatically identify the position of the white mark or color mark on the material, and accordingly trigger the corresponding control action (such as cutting, reel change, etc.).

High-quality Body Material

We use high-quality materials for the body, such as Standard carbon steel baking paint or optional stainless steel.

User-friendly Design

Our products can monitor working status and provide alarms. They can be easily configured to suit your requirements.

Intelligent Control

The man-machine interface uses a 7″ color touch screen, PLC and microcomputer control. It is configured according to the structure and characteristics of different rewinding materials with different requirements to achieve intelligent control.

1. Deviation Correction System

iFeeder’s Rewinder Machine Deviation Correction System is an advanced system specifically designed to accurately control material deflection during the rewind process. The system uses advanced sensors and algorithms to monitor the position and deflection of the material in real-time and quickly corrects the deflection with a precise adjustment mechanism.

- Adaptable to a wide range of materials

- Flexible adjustment

- Improvement of the product's side edge neatness and precision

2. Fast and Slow Lift Function

We use an AC servo motor drive, which can precisely adjust the speed and torque of the motor to meet the needs of different working conditions. The fast lift mode can be selected when fast winding is required to increase productivity, while the slow lift mode can be selected when fine control or handling of special materials is required.

- Flexible switching speed

- Guaranteeing smoothness and continuity

- Meet the needs of different working conditions

3. Linkage Third-party Equipment Combination Automated Production Line

iFeeder integrates equipment from various manufacturers using its proprietary technology to create a cohesive and efficient automated production system for rewinding, printing, coding, labeling, etc.

- Improving business productivity

- Cut down on 5 to 10 or more manual jobs

- Compatible with multiple devices

Rewinder Machine Solution Application Videos

We continue to amaze our customers with our unparalleled quality.

Film Rewinding Application Videos

Paper Rewinding Application Videos

Label Rewinding Application Videos

Optional Expanded Configuration

iFeeder has a technological advantage and offers customer-centred, customized solutions to address problems in various industries based on their requirements.

DMN Coding Machine

WDJ Coding Machine

UCS Coding Machine

DK Coding Machine

UV Inkjet Printer

ClJ Inkjet Printer

TIJ Inkjet Printer

Laser Inkjet Printer

Digital Inkjet Printer

Small character inkjet printer

Plasma Processor

Labeling Machine

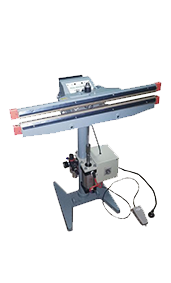

Sealing Machine

High Temperature Drying Function

FAQ About Rewinding Machine

Table of Contents

What is the speed of rewinding machine?

iFeeder’s rewinder operates at speeds of 60-100 metres per minute and supports a real-time rewinder speed display with adjustable speeds.

What are the different types of winding machines?

iFeeder has both tabletop and horizontal rewinding machines and can be customised to look and function as you wish.