Card Feeder Machine

By adopting advanced mechanical design and technology, we ensure that each card can be fed accurately and without errors, regardless of the card’s material, thickness, or size.

- Made of 201 Stainless Steel

- High-volume Processing of Card Feeds

- Belt Running Speed 0-120m/min or Higher

Automatic Care Feeder Supplier

iFeeder has over a decade of expertise in card feeder manufacturing, specializing in friction & vacuum technology. Our skilled tech team crafts tailored card feeders, swiftly resolving card feeding challenges and seamlessly integrating into diverse production lines. The automatic card feeder is particularly suitable for all kinds of sheet products: certificates of conformity, game cards, shopping cards, greeting cards, prize redemption cards, and so on. Let us provide you with customized card feeder solutions today.

Related Recommended Products

Benefits from iFeeder Card Feeder

iFeeder will endeavor to provide the best possible product experience for our customers.

Precision and Stability

iFeeder’s patented card-feeding technology with up to 98% stability.

Adjustable Card Stacking Port

Based on the size of the card, our card feeder can be flexibly adjusted with a simple operation.

Multiple Stacks at Once

Depending on the specific product size, generally 100mm cards can be stacked 200pcs.

Long Term Technical Support

Confident in our card feeder tech, we offer long-term support to ensure customer peace of mind.

Convenient Installation

The card feeder is compact and lightweight and does not require complicated tools to install.

Direct Factory Price

iFeeder offers you the best competitive price. Reject third-party markups.

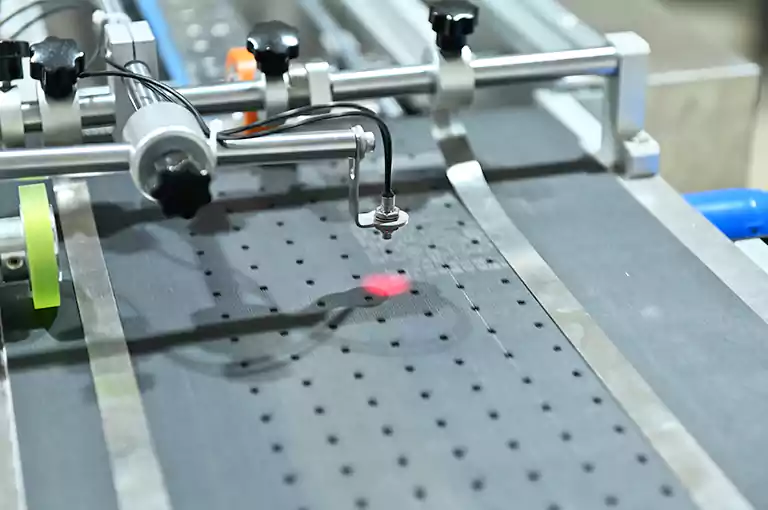

1. Double Card Detection Sensor

Our card feeder is equipped with a self-developed double card overlap detection function, which can automatically detect and reject double cards that have been misdirected, reducing manual intervention and greatly improving production efficiency.

- Real-time monitoring and feedback

- Improving the quality of card post-processing

- Ensure that each card is accurately transmitted

2. Integration with Other Equipment

Our automatic card feeders are easy to install and have the capability to be integrated into automated packaging lines, helping you to better handle the subsequent processing of your cards, such as various printing, labelling, wrapping and so on.

- High compatibility with existing systems

- Integrated inkjet printer, coding machine, labelling machine, etc.

- Achieve a higher level of automation

3. Efficient Completion of Card Feeds

Our advanced servo motors, featuring continuously refined parameters and power ranging up to 500-1000W, efficiently manage high-volume card feeding, with actual product-dependent efficiency.

- Configure belt speed on demand

- Simple operation to adjust the speed

- Suitable for quick supply of bulk cards

Some Application Videos

iFeeder has successfully helped many enterprises to complete card feeds efficiently, stably and accurately.

Multiple Different Card Feeds Solution

Card Feeding Test

High-speed Card Feeding Test

Optional Expanded Configuration

The card feeder integration of iFeeder coordinates different equipment systems to accomplish better automated production lines.

DMN Coding Machine

WDJ Coding Machine

UCS Coding Machine

DK Coding Machine

UV Inkjet Printer

ClJ Inkjet Printer

TIJ Inkjet Printer

Laser Inkjet Printer

Digital Inkjet Printer

Small character inkjet printer

Plasma Processor

Labeling Machine

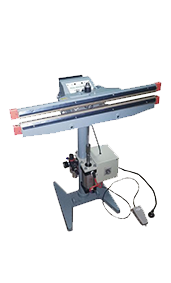

Sealing Machine

High Temperature Drying Function

FAQ About Card Feeder

Table of Contents

What are the three types of card feeders?

They are generally divided into Direct card feeders, friction card feeders, and vacuum card feeders.

1. Direct card feeders mechanically push the card directly into the process. They are suitable for cards with low requirements, uniform thickness, and hard materials. For example, ordinary plastic cards or cardboard cards.

2. Friction card feeders use friction wheels or friction belts to separate cards from the feed pile and transfer them to the machine. It is suitable for various types and materials of cards, especially used in high-speed production lines. Such as credit cards, membership cards, etc.

3. Vacuum card feeders attach and transfer cards to the machine through a vacuum attachment device. It is suitable for cards that need high precision and surface protection, such as smart cards, RFID cards, etc.