In recent years, China’s Yangcheng Lake hairy crabs have become more and more well-known, and gradually entered the public’s field of vision, their taste is delicious, the portion is sufficient, has also become the choice of everyone’s holiday gift; but to improve the sales of hairy crabs, the major factories to launch to the generation of gold cards, shopping cards, consumer cards, supermarket cards, gift cards, and so on.

In the face of sudden changes in the market, a card needs to have a unique number, QR code, bar code and label. After investing a lot of human resources, they found that not only the high cost and slow efficiency. Manually putting a sheet of cards to the conveyor for inkjet printing, and then one by one by the manual screening inkjet printing of the content is complete, and again after a manual one by one holding a scanner gun scanning inkjet printing of the two-dimensional code, bar code is correct, if the previous process is not a problem, then it will be entered into the next manual sorting one by one for the Labelling. Under the pressure of expensive labor costs and efficiency, we received the demand from manufacturers and actively responded and participated in providing implementable solutions.

In the initial confirmation, we carried out a series of research and development, design, simulation, and testing to arrive at a stable, reliable and implementable programme, and provide the programme to the manufacturer in a timely manner; in a week’s time the two sides repeatedly raised objections and resolved them, and finally decided to implement the programme.

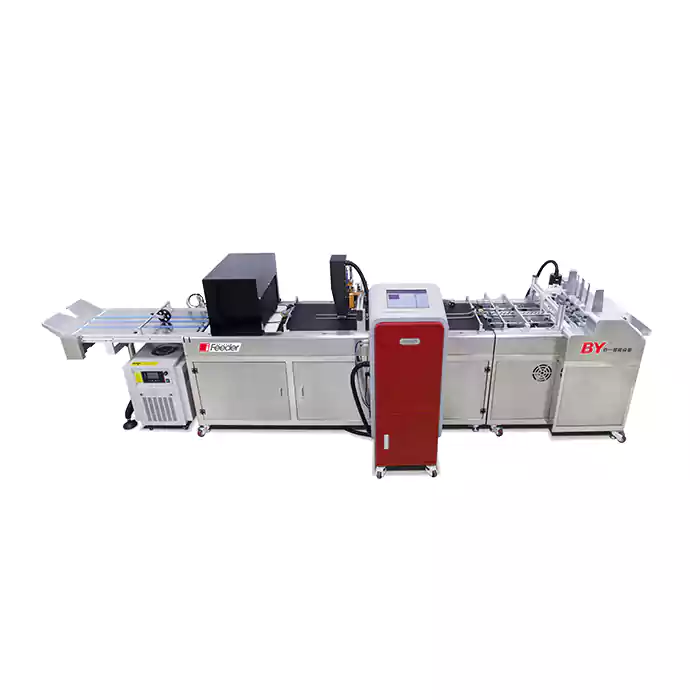

Uses the way: by one man will the whole stack of cards into the storage material warehouse, through the friction type feeds one sheet transmits to the automatic corrective mechanism carries on the card position guide the correct work, because the product distortion will impression the inkjet prints the content and affixes the label the accurate position; Then after the plasma processor carries on to the card surface the processing, the main function is in order to the back UV inkjet printer ink adheres to in the card; The processing finished the surface Goes in the UV inkjet printer to carry on the content printing; Then goes to the vision camera high speed takes the picture automatically to check whether the printing content is complete, whether has the heavy shadow, whether is fuzzy, whether has the printing to the content, if the detection fails, behind the automatic sticker labelling machine will not output to stick the label signal, in the tail directly kicks out the bureau, the product no longer enters in the qualified product the collection structure; If prints the content to be qualified, will enter in the automatic sticker labelling The machine carries on the labelling, finally according to the order to continue neatly stacks together.

Expensive labour costs are kept under control throughout the process, with only one person constantly loading product and a qualified picking area that consistently sends other workers straight to the packer.