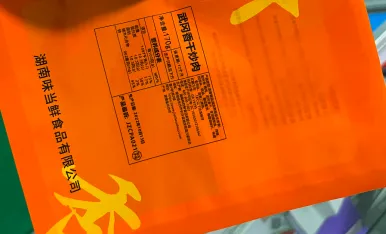

Food labeling refers to all attached labels, tags, text, graphics, symbols, and descriptors on or attached to food packaging containers, which describe the quality characteristics, safety characteristics, and instructions for the consumption or drinking of food. It is one of the most important bases for consumers to understand the content of the product and make healthy choices. Therefore, how to create accurate, clear, and compliant food labels has become an issue that food manufacturers must deal with.

I. Clear Labelling Content Requirements

Firstly, food labeling must be created based on local legal and regulatory requirements. The requirements for food labeling may vary from country to country and region to region, but they usually include the following aspects:

Product name: The product should be described clearly and accurately, avoiding misleading or ambiguous language.

Ingredient list: list all ingredients, including additives and processing aids, so that consumers can clearly understand the product.

Nutrition Facts Table: Provide the amount of key nutrients such as energy, protein, fat, carbohydrates, sodium, etc. per 100g (or per serving) of the food.

Allergen information: If the product contains any common allergens (e.g. nuts, dairy products, gluten, etc.), they must be clearly labeled.

Manufacturer information: Include the manufacturer’s name, address, and contact information for consumer inquiries or complaints.

Storage conditions and instructions for use: Provide the best conditions for preserving the product and how to use it to ensure product quality and consumer safety.

Date of Production and Shelf Life: labels the date of production and shelf life of the food to ensure that consumers are buying fresh and safe food. The production date is usually labeled as month and year.

Food Production Licence Number: indicates that the food manufacturer has obtained a production license, in line with food safety requirements.

Net content and specifications: Mark the net content of prepackaged food and any unit container containing food quality or volume, usually expressed in grams (g), kilograms (kg), milliliters (mL), liters (L), and other units.

Product Standard Code: Reflects the quality and safety characteristics of the food, and is the basis for food production and inspection.

II. Design Label Layout and Style

The layout and style of labels are equally important, as they directly affect the readability and attractiveness of the information. We recommend using easily recognizable fonts and font sizes to ensure that the information is clear at a glance. Avoid using too many colors or patterns to avoid interfering with the reading of the information.

III.Creativity and Personalization

Based on keep the information accurate and easy to read, try to add some creative elements to make the label more personalized and attractive, and briefly introduce the brand story or product features on the label to increase the consumer’s sense of identity and goodwill toward the brand.

IV. Use of Specialized Equipment

To improve the efficiency and accuracy of label production, professional equipment can be used, which generally includes food label printers and their related supporting equipment. Food label printers are devices specifically designed to print food labels, which can quickly and accurately print labels containing food information, production dates, shelf life, ingredient lists, and other key content. These printers usually support a variety of printing methods, such as thermal printing, inkjet printing and so on.

A labeling machine, on the other hand, is a device used to automatically affix printed food labels to food packaging. Depending on the degree of automation, labeling machines can be categorized into manual, semi-automatic, and fully automatic types. When choosing, companies should consider reliable manufacturers, such as iFeeder, which provides professional food label feeding, printing and labeling integrated equipment. The use of professional equipment can help you automatically complete the process of food label printing and labeling in large quantities to improve production efficiency, and the accuracy of label attachment is extremely high, greatly reducing the returns and complaints caused by labeling errors.

V. Audit and Testing

We conduct rigorous audits and testing before labels are officially used. This includes content audits, regulatory audits, and print testing. Of course, we can also invite some consumers to give feedback on the labels to understand their experience and valuable opinions.

In short, creating food labels is a complex and detailed process that requires food manufacturers to invest a great deal of time and effort. Regardless, companies need to follow food labeling regulations and use automated equipment to help them improve the accuracy and productivity of their food labels so that they can provide consumers with safe, transparent, and healthy food choices.