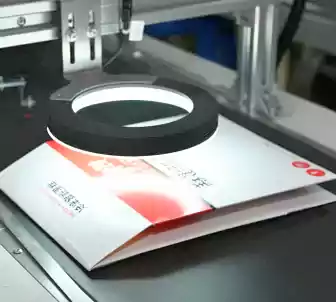

Automatic Paper Feeder

We achieve seamless and efficient batch handling of diverse paper types, accommodating variations in material, dimensions, and thickness without compromise.

- Handles over 300 Sheets of Paper Per Minute (100mm sheet for example)

- Longer Than 8h Trouble-free Operation

- Precise Positioning without Paper Jam

Custom Paper Feeder Machine Manufacturer

iFeeder specializes in customized paper feeders, providing efficient, stable, and accurate paper-feeding solutions for the printing, packaging, and other paper-handling industries. We design and manufacture them according to your unique requirements to ensure perfect adaptation and integration into your business production process. Our patented controllers enable coordinated and centralized control between equipment, improving compatibility and reliability. Contact iFeeder and let us help you optimize your business.

Related Sheet Feeder Recommended Products

Benefits from iFeeder Paper Feeder

Meeting the paper supply needs of the enterprise’s production.

High-speed Operation

Our friction paper feeder belts achieve speeds of up to 120 meters per minute or faster, enhancing feeding efficiency significantly

High Stability

Our paper sheet feeders employ advanced feeding technology for unparalleled stability, preventing paper jams and distortion, and ensuring seamless paper supply.

Factory Direct Sales

We are an original equipment manufacturer offering reasonable factory prices and rejecting middlemen.

Operational Simplicity

iFeeder’s automatic paper feeder is controlled by a touch screen and PLC, the equipment is easy to set up and adjust, and operators can be easily operated.

Long-term Durability

We use durable and adaptable aluminum materials and 201 stainless steel designs, which are suitable for long-term use and have high durability.

After-sales Service and Support

We provide timely and effective after-sales service and long-term technical support to ensure that your equipment always runs well. Solve your worries.

1. Accurate Paper Feeding

We utilize our paper feeding patents, configured with sensors and paper position correction features, and an anti-jam design to ensure that any type of paper is fed to other processes accurately and without double paper.

- Over 10 years of proven technology

- Reduction of paper consumption

- Fast batch processing of paper feeds

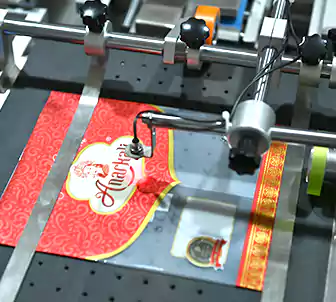

2. Installation to Line Integration Automation

The paper feeder mechanism can be integrated into the production line with conveyor belts, printers, labeling machines, and other equipment to complete the paper spraying patterns, dates, bar codes, labeling, and other process.

- Highly compatible

- Reduction of a few simple manual labour jobs or more

- Adjustment based on production requirements

3. Adjustable High-capacity Paper Stacking Port

Our stacking port is flexible and adjustable, can be adjusted according to the size of your paper to adapt to your paper products, to 100mm paper, for example, a one-time can be put 200pcs.

- Easy adjustment

- Highly flexible

- Improving work continuity

Wide Range of Application Industries

Our paper feeder mechanisms are of great importance in different fields and fulfill the efficient requirements of paper feed in various industries. For example, handling paper packaging and labeling paper feeds, handling paper feeds for the printing industry, handling paper-based manual feeds for electronic products, etc.

Some Sheet Feeder Application Videos

iFeeder will endeavor to serve its customers and strive for their satisfaction.

Vacuum Paper Feeding Solution

1000mm Width Paper Feeding Solution

High-speed Sheet Feeding Solutions

Optional Expanded Configuration for DIY Paper Feeder

Our self-developed control system is integrated and can be combined with other third-party equipment to form a multi-functional production line to improve enterprise production efficiency.

DMN Coding Machine

WDJ Coding Machine

UCS Coding Machine

DK Coding Machine

UV Inkjet Printer

ClJ Inkjet Printer

TIJ Inkjet Printer

Laser Inkjet Printer

Digital Inkjet Printer

Small character inkjet printer

Plasma Processor

Labeling Machine

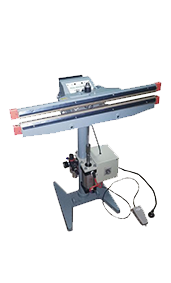

Sealing Machine

High Temperature Drying Function

FAQ About Paper Feeder Machine

Table of Contents

What are the different types of paper feeders?

There are two types of paper feeders, friction paper feeders and vacuum paper feeders:

1. Friction paper feeders use friction to separate paper from the stack and feed it into the production line.

2. Vacuum paper feeders use suction to lift paper from the stack. The paper is sucked up by vacuum suction cups and fed into the production line.

Each type of sheet feeder has advantages and applications, and choosing the right one can significantly improve efficiency and processing quality.

What is a paper feeder used for?

The purpose of the paper feeder is mainly to automatically feed piles of paper from the feeder into other workflows one sheet at a time individually in the production process of printing, labelling, packaging, etc., to be able to complete the paper supply more efficiently.