Quality Management

Throughout the entire production process, we follow the raw materials, motors, accessories, inspections, tests and so on.

Quality is the Philosophy that iFeeder Adheres to

Careful Selection of High-quality Raw Materials

We know that high-quality raw materials are the basis for creating high-quality products, but we also to consider the hardness of the material in some of the special process locations. Therefore, the body is mainly made of aluminum and high-quality 201 stainless steel raw materials. At the same time, we test all major raw materials for physical properties, including tensile strength, impact toughness, wear resistance, etc., to ensure that they meet production standards.

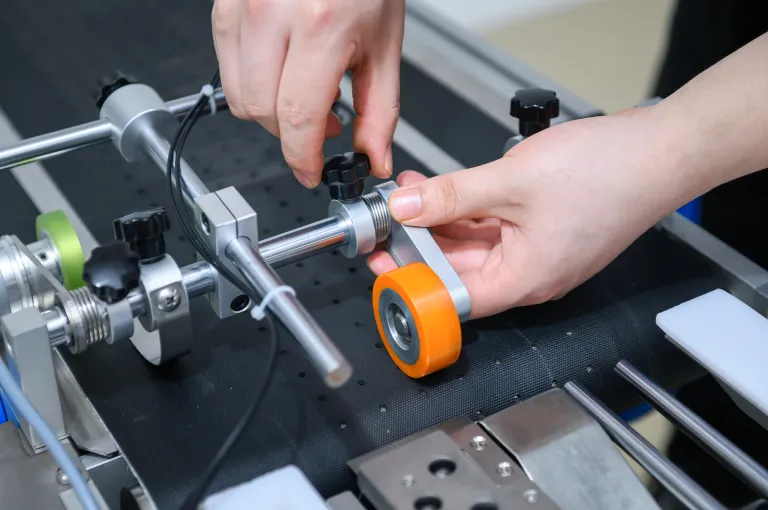

Precision Parts in Pursuit of Excellence

Fittings are also vital to the operation of the equipment, and we custom-machine precision fittings to exacting standards.

Precision measuring tools are used to accurately measure the fittings to ensure that they fit the machine, a perfect fit is conducive to improved product stability and reduces the effects of vibration.

Continuous Optimization of Motors

We choose famous brand motors and cooperate with them for a long time. We optimize the voltage, current, power, temperature rise, thermal resistance, and other parameters of the motors through rigorous testing and feedback of data accumulated in the market, to achieve the best results and ensure the high efficiency and compatibility of the motors;

Manual Assembly is Indispensable

We have a team of experienced assembly workers, who are familiar with every detail of assembly, and in strict accordance with the assembly standards; manual assembly of precision and meticulous control is better, and more stable for the operation of the equipment, to reduce the impact of bad assembly to the machine.

Rigorous Inspection and Test Runs for Superior Performance

We have a professional inspection team to carry out a strict testing process for each device, including appearance inspection, stability test of the Feeding function, printing accuracy, speed, compatibility, safety marking, and many other indicators. Products that fail the test will be isolated and disposed of.

Only equipment that passes strict testing can provide customers with an excellent experience.

Do You Want to Customize a Multifunctional Intelligent Pagination Printing Solution?

Our team will get back to you within 24 hours