Rigid packaging refers to the filling or removal of the contents of the package, the shape of the container basically does not change, and the material is hard or firm texture of the package, this type of packaging, some of the texture is firm, and can withstand the impact of external forces, and some of the texture of the hard, but brittle.

Unlike flexible packaging, which can change shape, rigid packaging is designed to provide strong, stable protection for products during transport, storage and handling. Materials commonly used for rigid packaging include.

1. Plastics: Commonly used for bottles, containers and trays. Examples include PET, HDPE and polypropylene.

2. Glass: Commonly used for bottles and jars, especially in the food and beverage industry.

3. Metal: Used for cans, canning jars and certain types of containers. Common metals include aluminum and steel.

4. Paperboard and cardboard: used for boxes, cartons and other sturdy containers.

Rigid packaging is widely used daily, almost covering a wide range of fields from food and beverages to electronic products, cosmetics, medical supplies and so on. The following article mainly focuses on introducing cardboard boxes in rigid packaging.

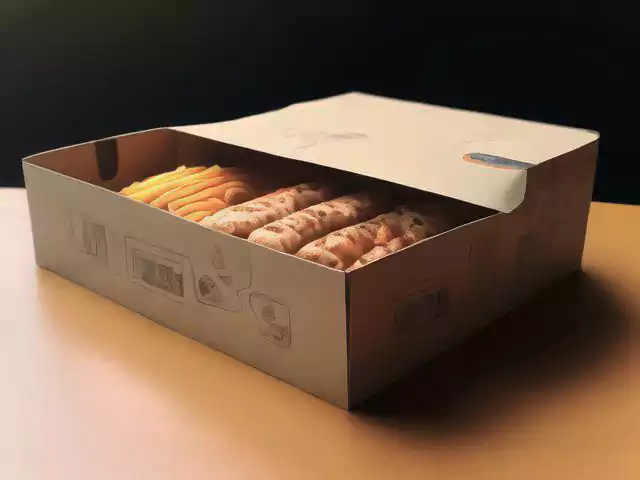

Rigid cardboard boxes include standard cardboard boxes, drawer-type cardboard boxes, window-type cardboard boxes, profiled cardboard boxes, and folding cardboard boxes.

The packaging of our common gifts, cosmetics, electronic products, express boxes, chocolate boxes and other goods are all of the standard type, they have certain advantages in use.

1. Sturdy and durable: cartons and cardboard boxes are made of rigid materials that can withstand a certain degree of pressure, impact and extrusion, effectively protecting the internal merchandise from damage. Especially for fragile, easily deformed goods, cartons and cardboard boxes provide a reliable protective barrier.

2. Enhance brand image: The exquisite appearance and personalized design of rigid cardboard boxes can enhance the grade and brand image of the product.

3. Convenient for mechanized production and transportation: the production process of cartons and cardboard boxes are easy to achieve mechanization and automation, which improves production efficiency. At the same time, its lightweight, sturdy features also facilitate loading, unloading, handling and logistics transport, reducing the breakage rate and transport costs.

So how do you utilize their strengths and increase productivity?

Among them in the enhancement of brand image can be improved by improving the quality of printing patterns, colors, etc., so that the packaging and brand image to maintain consistency, and enhance consumer awareness of the brand and goodwill.

In improving production efficiency can be introduced into automated production equipment, such as automatic paging machines, automatic labeling machines, automatic sealing machines, etc., to improve productivity while also reducing labor costs.

Rigid packaging is an important form of packaging, in the protection of products, enhancing brand image, promoting environmental protection and other aspects that play an important role, for our life to bring more convenience and beauty.