Automatic Paging Machine

Using high-precision sensors ensures accurate pagination every time and is compatible with printers, labeling machines, etc.

- Professional 14 Years of Experience

- 100+ Patents, Intellectual Property Rights

- Highly Efficient, Stable and Compatible

Advanced Paging Machine Manufacturer from iFeeder

Powered by our AI technology, iFeeder paging machines work with printers, encoders, and labeling machines. It creates QR codes, production dates, batch numbers, barcodes, and more with high stability and accuracy. Suitable for all packaging materials, sizes, cards, labels, and paper. Boost your productivity with iFeeder.

Related Recommended Products

Benefits from iFeeder Paging Machine

iFeeder gives you reliable quality.

Drop-type Stack Collection of Collecting Hopper

We have added a material collection device at the end of the conveyor, eliminating the need for manual collection.

Alarm Prompt After No Product

If there are no more products in the paging process, the machine stops applying them and alerts the staff.

Alarm Prompt After the Product is Stuck

An alarm alerts the operator if the pagination material becomes jammed.

Accurately Calculate the Number of Products Online

You can choose to use the calculator, which shows you in real-time how many products are being delivered in a single transmission.

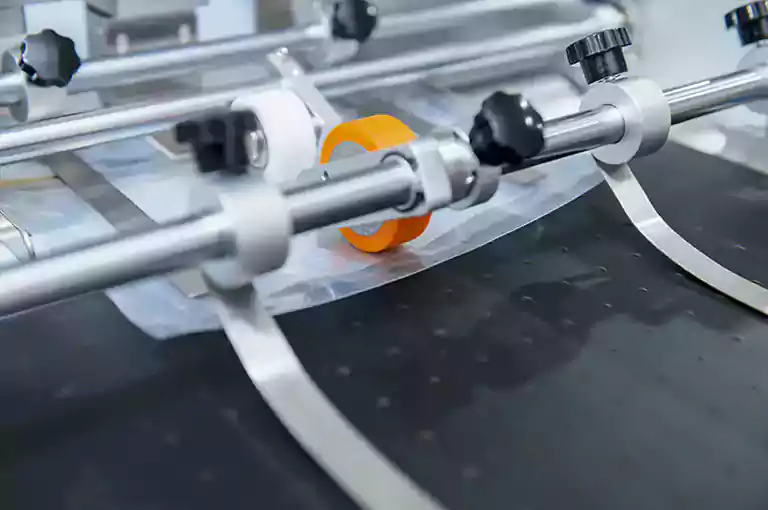

Negative Pressure Adsorption Function

You can choose medium and high-pressure fans installed at the bottom of the conveyor belt, and negative pressure adsorption of pagination items to achieve better paging effect.

High-speed Conveyor Belt

The iFeeder’s auto paging conveyor speed is fully adjustable, with a range of 0-120 meters per minute and customizable to meet your needs.

1. iFeeder R&D Results-Automatic Deviation Correction

Technical leaders led the excellent R & D team to continue to develop and innovate, iFeeder auto-correction function can help you in the process of paging to maintain the correct position of the transmission to the next production process, improve the correctness of the spray code, labeling.

- Up to 98% autocorrect success rate

- Achieve a very low loss of products

- Responds in milliseconds

2. Self-developed Double Sheet Detection Function

iFeeder’s pagination machines are equipped with double sheet detection to ensure that no pairs of sheets are processed during the pagination process. This is essential for the accurate processing of single sheets of material, such as coding, labeling, calculations, and so on.

- Approximately 0.2% false alarm rate

- Continuity of work and efficiency

- Rapid response

3. Important Visual Inspection Equipment

The vision detection function of the iFeeder ‘s paging machine is a use of advanced image processing technology, non-contact automatic detection, and identification of materials, which can identify the location of the material, direction, etc., in addition to more complex identification of materials, including shape, color and other accurate identification.

- High detection accuracy

- Alternative to manual inspection

- Adjust parameters and thresholds as required

Some Solution Application Videos

After years of feedback from the market, iFeeder is constantly optimizing its products to guarantee a good experience for our customers.

Paper Paging Solutions

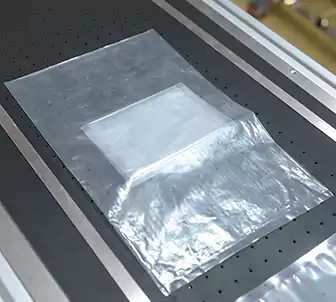

Sheet Paging Solutions

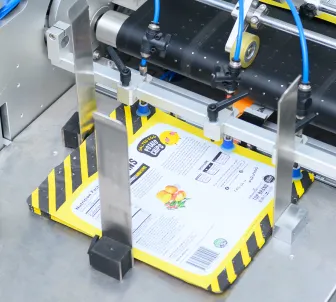

Carton Package Paging Machine Solutions

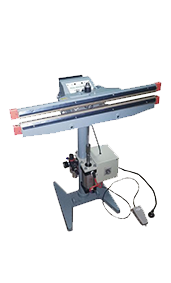

Optional Expanded Configuration

With iFeeder’s technical team, our products have core competencies and can be combined with third-party equipment to form automated or semi-automated production lines to provide production efficiency.

DMN Coding Machine

WDJ Coding Machine

UCS Coding Machine

DK Coding Machine

UV Inkjet Printer

ClJ Inkjet Printer

TIJ Inkjet Printer

Laser Inkjet Printer

Digital Inkjet Printer

Small character inkjet printer

Plasma Processor

Labeling Machine

Sealing Machine

High Temperature Drying Function

FAQ About Paging Machine

Table of Contents

What is a paging machine?

Paging machine is a device used to automatically separate stacks of papers, plastic bags, boxes or cards and other materials. It can separate these items into individual pieces and transfer them to a conveyor belt for subsequent processing such as coding, laser marking, etc.

Which packaging materials are suitable for paging machines?

Plastic bags: including all kinds of film bags, stand-up pouches, M-shaped pre-made bags, three-side-seal pre-made bags, four-side-seal pre-made bags, pre-made bags with zip, etc.

Paper products: such as paper boxes, paper bags, cards, coated paper and so on.

Aluminum foil bags, PE, PET, OPP and other films

What are the advantages of our paging machines?

1. Low failure rate: our pagination printing machine has a crooked, jamming failure rate of only 2%, while most peers reach 20-30%.

2. Self-developed system: Our control system is written by our team, we can upgrade and maintain the system remotely according to the customer’s needs, and the coordination between the equipment is high, which is far ahead in the industry.

3. Wide range of industries: Our solutions are used in agriculture, the pharmaceutical industry, the food industry, the daily necessities industry, and so on.

Do our products have international certificates?

Yes, we are CE certified and other certifications are in progress.

Is it easy to maintain a pagination machine?

Yes, we will provide installation instruction and operation training, and long-term technical support. In addition, third-party equipment wearing parts are easy to purchase locally, and we also support the shipment of wearing parts from the factory.